Vertical Single-stage Inline Pumps

Vertical Single-stage Inline Pumps

Our pumps have a wide variety, diverse styles and excellent quality. You can get the latest price and product information by sending an email.

Product introduction

ISG type vertical single-stage centrifugal pump, GR type hot water pump, IgY type light oil pump

ISG series pumps are vertical structure of is and KT pumps. The flow range is 2.5-1600m ³/ h. The lift range is 2-145m. It is mainly used for pumping clean water, light oil and non corrosive or weak corrosive liquid. The maximum temperature of medium is 80 ℃.

ISG pump has the same size of water inlet and outlet, 180 degree arrangement, and can be connected in series in the pipeline.

The working pressure of the pump is 1.6Mpa, and the pump with working pressure greater than 1.6Mpa can also be provided, so these pumps are suitable for the occasions with higher inlet pressure (such as closed circulation system of air conditioning and heating).

The standard vertical motor transmits power through elastic coupling, so it has the characteristics of smooth operation, low noise and small vibration.

There are two kinds of shaft seal: mechanical seal and soft packing seal. If the shaft seal part is cooled (with clean water at normal temperature), it can transport the liquid not more than 130 ℃ (IGR type hot water pump). Copper impeller and stainless steel shaft are used to transport light oil (IGY light oil pump).

Main parts manufacturing materials: pump body, pump cover – cast iron or ductile iron; Impeller – cast iron or cast copper; Shaft – carbon steel or stainless steel.

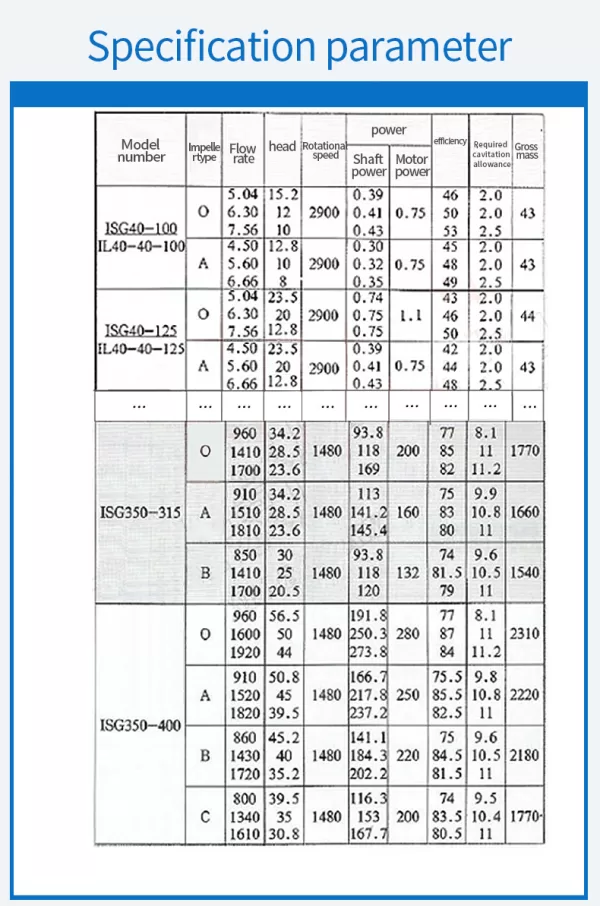

The meaning of the numbers in the pump model: isg100-200100-inlet and outlet diameter (mm), 200 impeller nominal diameter, 200 inlet diameter (mm), 150 outlet diameter (mm), 250B impeller diameter after the second cutting.

After placing the order, please contact the salesperson to provide you with the installation plan as soon as possible. Please construct the foundation according to the dimensions on the foundation drawing.

2. Before installing and using the equipment, please carefully read the product installation and operation manual. If you have any questions, please call our 24-hour service hotline at 400-8570-567 or 13506440087. We will have professional technical personnel to coordinate with you.

3. Before leaving the factory, the equipment undergoes a water and pressure test. If there is a small amount of water stored in the pump and it is installed and used in colder areas, please ensure that the storage and installation environment of the pump will not cause the water in the pump to freeze. Improper storage causing pump damage will be the responsibility of the user. Please empty the equipment and pipelines in a timely manner when not in use in winter to avoid damage caused by frost

4. Before using the pump, please ensure that the power supply voltage is stable, there is a protective device (which can be matched with a control system), the environment is dry, and the pipeline valves are installed properly. If you have any questions about installation and use, you can call our factory’s service hotline. Any damage to the pump caused by improper installation or use shall be the responsibility of the user.

6. It is recommended that you install a filtering device on the imported pipeline and regularly clean it to ensure the reliability and service life of the pump operation

Dear customer, please check if the packaging of the goods is damaged upon receipt, and if the products, manuals, certificates of conformity, accessories, etc. are complete. If there are any abnormalities, please take photos immediately and contact the customer service manager. Please make sure to sign for it in person. Any loss or damage to the goods caused by not signing for it or not inspecting the goods will be the sole responsibility of the recipient.